当前位置:首页 > Product Center > Ceramic&CBN

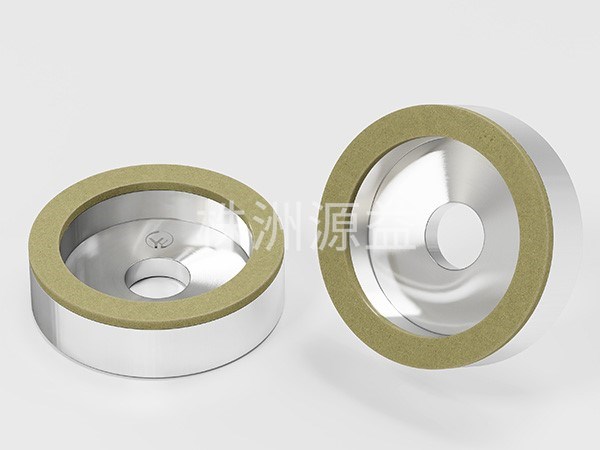

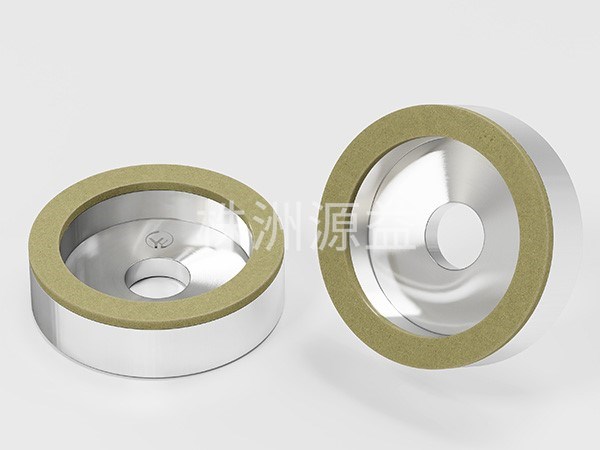

Product introduction: Good self sharpening, easy to repair, grinding wheel with air holes, conducive to chip removal and heat dissipation. High machining accuracy, high tensile modulus of elasticity, wide trial range, good machining space, and sharp cutting.

Immediately consult

| Yuan Yi grinding wheel rotation speed meter | ||||

| Rotational speed | Diamond wheel SDC | Boron nitride grinding wheel CBN | ||

| Dry grinding | Wet-milling | Dry grinding | Wet-milling | |

| Resin grinding wheel B | 700-1300 | 1300-1800 | 800-1400 | 1400-2000 |

| Ceramic grinding wheel V | 1000-1800 | 1200-3600 | 1600-2000 | 1600-4800 |

| Electroforming grinding wheel P | 600-1200 | 1000-1800 | 600-1200 | 1000-1800 |

| Metal grinding wheel M | 500-1000 | 1400-1800 | 500-1200 | 1500-2100 |

| The difference of different bond grinding wheel | |||||

| Binders | Characteristics of grinding wheel | Application | Symbols | Life Span | Grinding |

| Electroplated Bond | Good grinding efficiency, strong grip, wear resistance, no need to repair. The grinding workpiece has high precision and less wear consumption. Any complex shape or very small grinding wheel can be manufactured, the substrate can be reused. | Widely used in glass, ceramics, lenses, gemstones, ferrite magnetic materials, crystals, special surfaces of various materials, small hole grinding and irregular opening grinding tools, forming grinding wheels. Metal materials such as chilled cast iron, gray iron, cast alloy steel, titanium alloy, mechanical processing, complex forming grinding, and dressing rollers. | P |

|

|

| Resin Bond | High compressive strength, good wear resistance, a certain degree of flexibility and toughness, not easy to burn the workpiece and produce debris, good processing surface, with heat and alkali resistance. | Widely used in carbide, optical glass, precision cermets, steel, aluminum, copper, iron, high-speed steel, titanium steel, stainless steel, wood, rubber, plastic, stone, heat-resistant alloy steel, semiconductor, magnetic materials and metal materials, such as waste grinding, rough grinding, semi-precision, precision grinding, honing and other ultra-precision processing, polishing and cutting etc. | B | ||

| Vitrified Bond | Self-sharpening, easy to repair. The grinding wheel has air holes for row cutting heat dissipation, high machining accuracy, high tensile elastic modulus, wide application, good cutting space, cutting sharp. | It is widely used in superhard cutting tools, material processing, hard alloy blades, diamond composite (PCD tools) , single crystal PCBN tools and composite. Crankshaft, long shaft, screw, camshaft, micro-bearing, large precision parts, instruments and other alloy grinding, grinding. | V | ||

| Metal Bond | High hardness, wear resistance, can widely meet the requirements of complex shape and have a certain porosity of the workpiece, not easy to burn the surface, long life, good wheel retention, high hardness, high tensile elastic modulus. | Applied to tungsten steel roll-ring forming glass grinding edge molding, ceramics, stone and other load grinding. Silicon wafer grinding molding, optical curve, potassium arsenide, silicon wafer grinding, iron powder core, etc. | M | ||

|

Comparison Table of Particle Sizes of Diamond and Cubic Boron Nitride |

|||||||||||

| General standard | China | England | European Community | America | Soviet Union | ||||||

| GB/T6406-1996 | ISO6106-1979 | FEPA-1977 | ANSIB74.16-197 | OCT 9202-80 | |||||||

|

|

|

West Germany | Japan |

|

|||||||

|

|

|

DIN 848-88 | JIS 4130-1982 |

|

|||||||

| Particle | Particle | Size | Particle | Particle | Size | Particle | Size | Particle | Size | Particle | Size |

| 22# | 18/20 | 1000/850 | 1001 | 18/20 | 1000/850 | D1001 | 1000/850 | 18/20 | 1000/850 | 16# | 1250/1000 |

| 24# | 20/25 | 850/710 | 851 |

|

850/710 | D851 | 850/710 | 20/30 | 820/600 | 20# | 1000/800 |

| 30# | 25/30 | 710/600 | 711 |

|

710/600 | D711 | 710/600 | 24# | 800/630 | ||

| 36# | 30/35 | 600/500 | 601 |

|

600/500 | D601 | 600/500 | 30/40 | 600/425 | 30# | 630/500 |

| 40# | 35/40 | 500/425 | 501 |

|

500/425 | D501 | 500/425 | 36# | 500/400 | ||

| 46# | 40/45 | 425/355 | 426 |

|

425/355 | D426 | 425/355 | 40/50 | 425/300 | 46# | 400/315 |

| 54# | 45/50 | 355/300 | 356 |

|

355/300 | D356 | 355/300 | ||||

| 60# | 50/60 | 300/250 | 301 | 50/60 | 300/250 | D301 | 300/250 | 50/60 | 300/250 | 60# | 315/250 |

| 70# | 60/70 | 250/212 | 251 |

|

250/212 | D251 | 250/212 | 60/80 | 250/180 | 70# | 250/200 |

| 80# | 70/80 | 212/180 | 213 |

|

212/180 | D213 | 212/180 | 80# | 200/160 | ||

| 90# | 80/100 | 180/150 | 181 | 80/100 | 180/150 | D181 | 180/150 | 80/100 | 180/150 | ||

| 100# | 100/120 | 150/125 | 151 | 100/120 | 150/125 | D151 | 150/125 | 100/120 | 150/125 | 100# | 160/125 |

| 120# | 120/140 | 125/106 | 126 | 120/140 | 125/106 | D126 | 125/106 | 120/140 | 125/106 | 120# | 125/100 |

| 150# | 140/170 | 106/90 | 107 | 140/170 | 106/90 | D107 | 106/90 | 140/170 | 106/90 | 150# | 100/80 |

| 180# | 170/200 | 90/75 | 91 | 170/200 | 90/75 | D91 | 90/75 | 170/200 | 90/75 | ||

| 200# | 200/230 | 75/63 | 76 | 200/230 | 75/63 | D76 | 75/63 | 200/230 | 75-63 | 180# | 80/63 |

| 240# | 230/270 | 63/53 | 64 | 230/270 | 63/53 | D64 | 63/53 | 230/270 | 63/53 | 240# | 63/50 |

| 280# | 270/325 | 53/45 | 54 | 270/325 | 53/45 | D54 | 53/45 | 270/325 | 53/45 | 280# | 50/40 |

|

|

325/400 | 45/38 | 46 | 325/400 | 45/38 | D46 | 45/38 | 325/400 | 45/38 | ||

Pre-use considerations

Dear customer, please check carefully after receiving the goods, if there is a quantity, size, material, gap or other damage problems, please stop using and contact us within 2 working days.

● before installing the grinding wheel, please turn off the machine power and find the grinding wheel marked with the direction of rotation, to the same direction of rotation with the machine tool, on the contrary, cutting is not sharp, it is difficult to play the performance of the grinding wheel.

●When the grinding wheel is loaded into the flange, please do not use the wooden hammer to knock the forced installation. During flange installation, the screws should be in the order of the diagonal position of equal torque, to ensure that tight, not loose.

●When using wet grinding process, please pay special attention to the grinding fluid can not be interrupted.

●Please do not change the shape of the additional grinding wheel after processing, if there is a need, please contact the company first.

●Do not use if the shape and size of the grinding wheel do not match the specified size of the grinder (outer diameter, thickness and aperture of the grinding wheel) .

●If any abnormality is found during the grinding process, the machine should be stopped immediately, and the reason should be checked and contacted with us to provide guidance service on-line 24 hours a day.

●If the base material of grinding wheel is iron products, please do not wipe away the rust inhibitor on its surface. If the base material is a ceramic product, please tap the side of the grinding wheel gently with a wooden hammer before installation, and check the sound of tapping.

●When the grinding is not sharp enough, the grinding wheel should be trimmed, if continued to use will appear overheating, overload and the possibility of wheel damage.

● hand operation is strictly prohibited during grinding wheel rotation, and hand and body contact with grinding wheel is also forbidden.

●A grinding wheel may generate sparks when used, so it should not be used in an environment where ignition or explosion is possible.